Customer requirements:

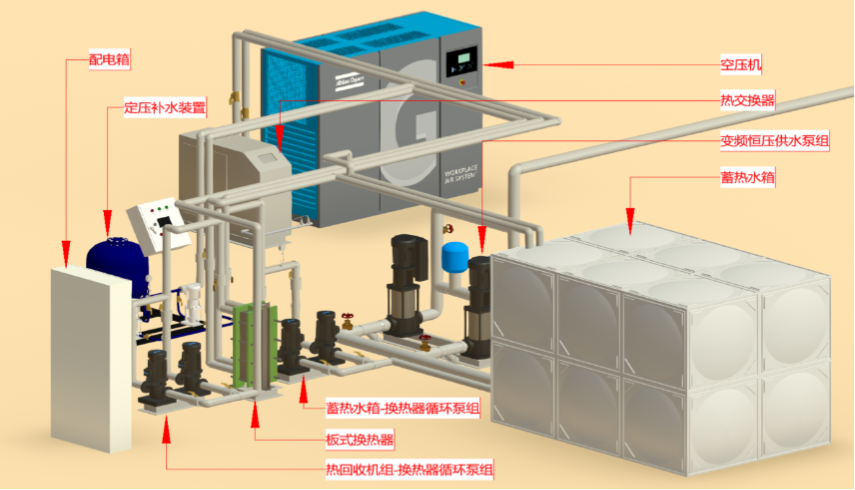

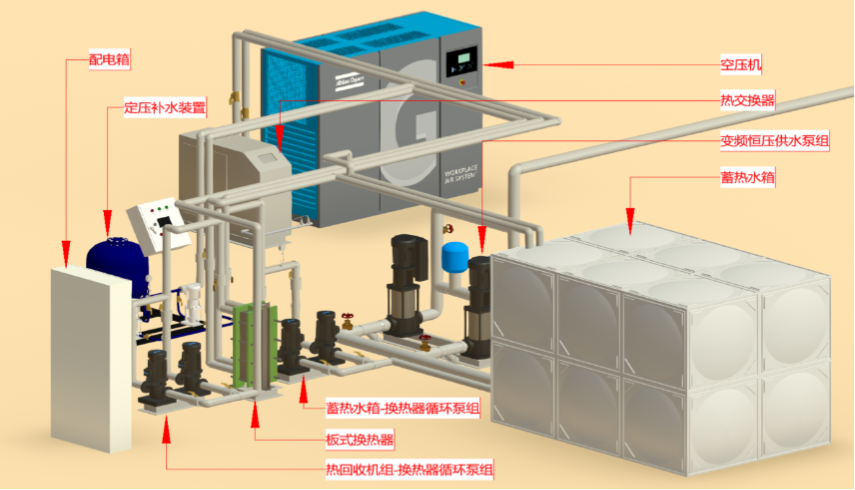

There is one 75KW air compressor unit in the customer's air compressor room, and the heat loss of the air compressor unit is relatively large, which needs to be discharged in a timely manner. Due to the fact that the air compressor room is located inside a closed workshop, the exhaust of the air compressor system can cause an increase in room temperature. Therefore, the customer wishes to install an air heat exchange system in the air compressor room to recover the heat emitted by the air compressor system and use it as a heat source for showering.

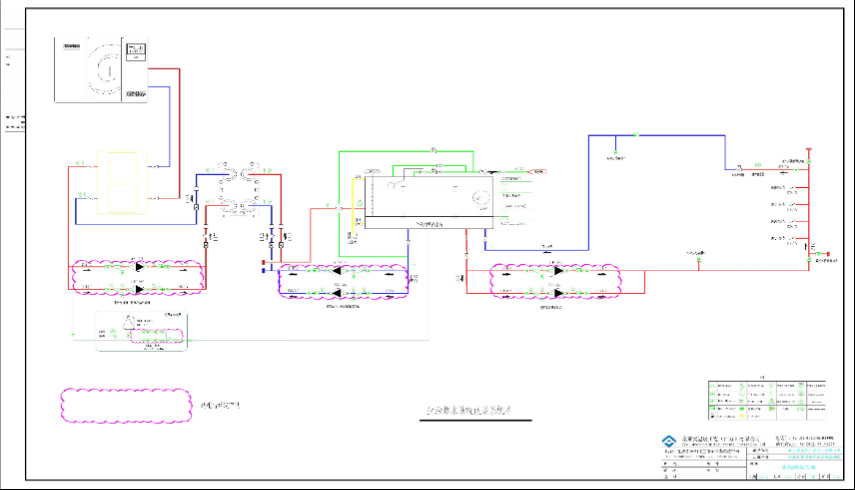

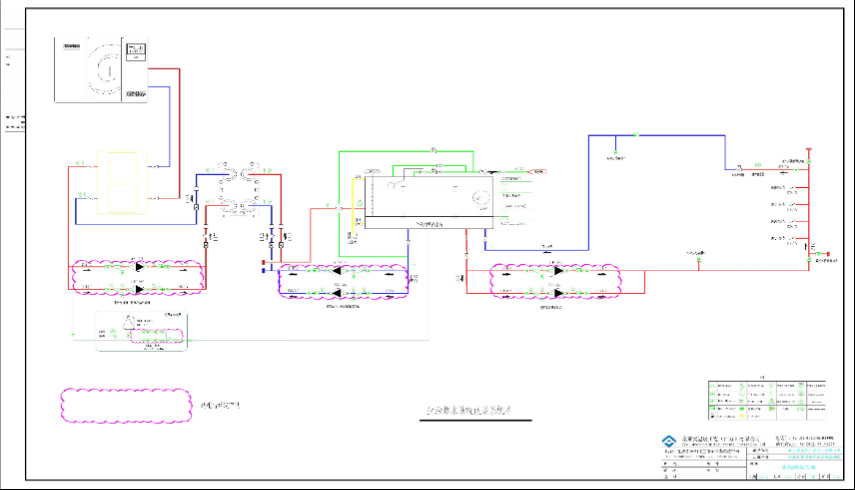

Using heat recovery equipment to collect the waste heat of the air compressor, and then exchanging heat with the water in the buffer tank through a plate heat exchanger. The heated water is collected in the insulated water tank and supplied to the shower room for use.

Room 101, Building 1, No. 77 Louyang Road,

Room 101, Building 1, No. 77 Louyang Road,  0512-65169005

0512-65169005

commercial@zyajs.com

commercial@zyajs.com